Welding aluminium cell connectors

With this method high cross-sections can be realized with small, thermally sensitive contact areas while at the same time maintaining good mechanical flexibility. This is necessary in order to transmit the high charging and discharging currents that occur with high power batteries with low thermal loss. Lighter, more flexible cell connectors made of aluminium can be made which allow for installment in smaller spaces than was possible with previous processes.

We weld for you

In cooperation with the Fraunhofer Institute for Laser Technology, Air Energy offers the welding of aluminum connectors as a service. Contact us to select the right connection technology for your application together with our employees.

Applications

Aluminum welded connectors are suitable for all applications in which high charging and discharging rates ~60 C are required, at the same time providing good connector flexibility. The process can be used wherever a large conductor cross-section is required for small, thermally sensitive contact areas in order to minimize thermal losses. This method is particularly suitable for prismatic cells with high charging and discharging currents. Due to the higher flexibility compared to conventional connectors, strain relief is also provided at the connection point, which reduces the rigidity of the connection.

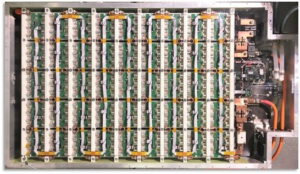

High power battery

This battery is a high-power battery based on Toshiba lithium titanate cells. 315 cells were connected in series to achieve a maximum voltage of 882 V. The nominal charging power is 300 kW, which corresponds to 40 C, with a peak of up to 400 kW (60 C charging rate) possible. This corresponds to a charging current of up to 600 A! Thanks to the special welding process, the cell connectors are significantly smaller and more flexible than conventional connectors while maintaining high conductivity, which reduces both costs and weight. The battery is also water-cooled and has a complete battery management system and high-voltage contacts.