Together with our clients, we develop customised battery storage solutions for unusual applications

We collaborate closely with our customers to define battery system requirements, estimate what is technically feasible, and develop an initial concept, pushing the technical boundaries as much as possible. We endeavour to deliver the maximum for our customers, no matter how stringent or unusual their requirements: Extremely lightweight, high performance, or compact design solutions, or specific applications, such as air or maritime.

Battery Prototyping

Together with the customer, we design battery concepts, which we construct together with our local suppliers and partners. We test the battery system against the customer's requirements and can thus ensure that the customer receives the battery he needs for his application. After a few months, the customer can use the battery in his application. We have already designed high-voltage batteries and small battery systems for our customers in the past. We pay attention to highest quality and careful work.

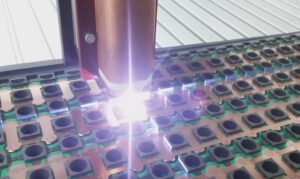

Small series production

At the request of our customers, we also produce batteries in small series at our site in Aachen. Together with the engineers who also developed the battery system and a very good contact to our suppliers, we can quickly set up a small series production. Here, too, we pay attention to high quality standards and develop individual test processes for each series.

Electronics development

At Air Energy, electronics development is inextricably linked to system development. Air Energy's battery management system for Li-Ion batteries has been in constant development since 2003, and is immediately available in several variants for new projects. Battery management systems, chargers and dischargers are developed by a single provider and, therefore, work flawlessly together. Safety-related functions (e.g., gauges, stop-charge, stop-discharge, etc.) provide built-in redundancy.

Software development

Matching the electronics, we also independently develop the software for the battery management system (BMS). Monitoring of limit values for voltage, temperature and current, diagnostics of the battery condition and the control of the battery system are basic functions of our software. The functions of the software can be individually adapted and expanded to meet customer requirements.

Thermal management

We design thermal solutions without active cooling to ensure our battery systems are space and weight-optimised. On the other hand, we develop active air or liquid cooling for high-performance applications.

Construction

Our highly experienced team develops creative solutions to overcome any space-related constraints for our battery systems. Not surprisingly, delivering lightweight and structurally demanding housing is one of our core competencies. This tall order is met by constantly introducing new materials and manufacturing processes.

Charging concept

Our battery is supplied with a charger specially designed for it. The interaction of our battery with the charger electronics ensures maximum service life and optimum protection against overcharging.

Discharging concept

Upon request, we supply batteries with a discharger. Dischargers are designed to lower battery state of charge as to increase transport safety and minimise battery aging upon prolonged storage.

Research network

In Aachen´s research landscape, our research and development projects rely on the following partners:

Institute for Power Electronics and Electrical Drives, RWTH Aachen University

www.isea.rwth-aachen.de

University of Applied Sciences Aachen

www.fh-aachen.de/

Professorship of Electrical Measurements and Sensor Technology, TU Chemnitz

www.tu-chemnitz.de/etit/messtech/

Laboratory for Machine Tools and Production Engineering (WZL), RWTH Aachen University

www.wzl.rwth-aachen.de

Institute for Automotive Engineering (ika), RWTH Aachen University

www.ika.rwth-aachen.de

Fraunhofer Institute for Laser Technology ILT

www.ilt.fraunhofer.de